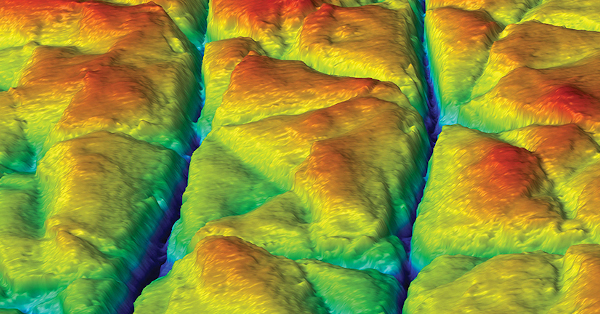

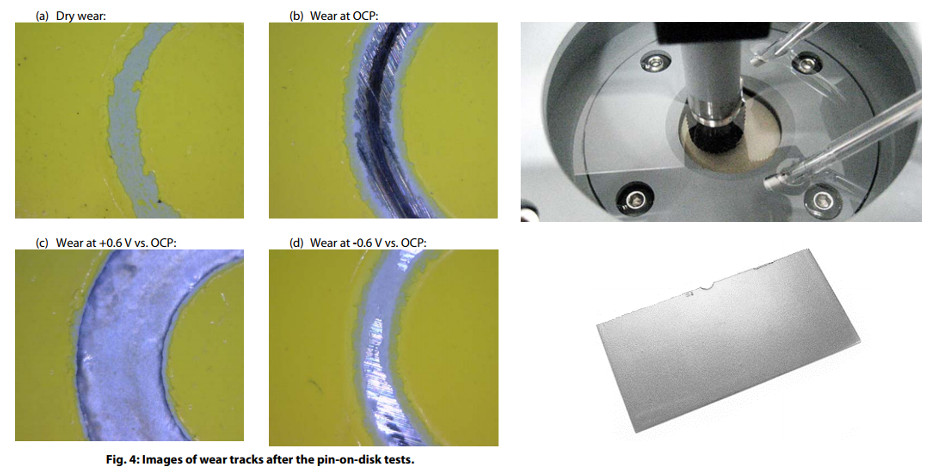

The study on tribocorrosion has evolved to be a very active research area, due to its application in a variety of industries, such as mining, oil, automotive, food, nuclear, offshore marine and biomedical. Tribocorrosion is a surface degradation process resulting from simultaneous tribological and electrochemical actions in a corrosive environment. Such a process cannot simply be predicted from the knowledge of isolated wear and corrosion behaviours of the material, since synergistic effects of these two processes can accelerate the mass loss in the tribocorrosion test. Tribocorrosion can cause material degradation, and affects the friction, wear and lubrication behaviour of the tested materials.

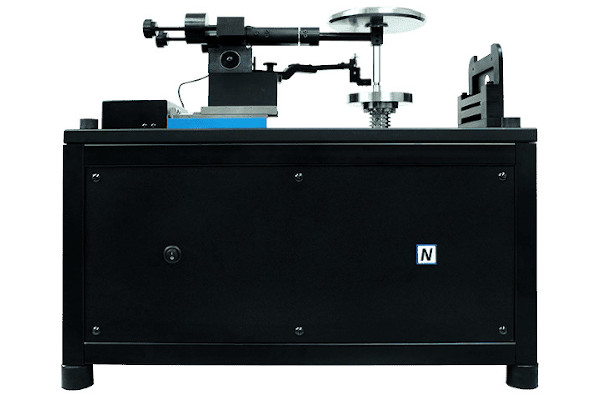

The Tribocorrosion Module of the Nanovea Tribometer provides effective and efficient measurements for evaluating and developing cost-saving materials critical for corrosion and wear protection in various industrial applications. The purpose of tribocorrosion research is the minimization of losses resulting from wear and corrosion and the enhancement of production efficiency, application performance, and most importantly the cost savings to allow industrial growth.

In this application note Nanovea use the T50 Tribometer to simulate the tribocorrosion process of the commercial acrylic urethane paints applied as floor/automobile coatings.