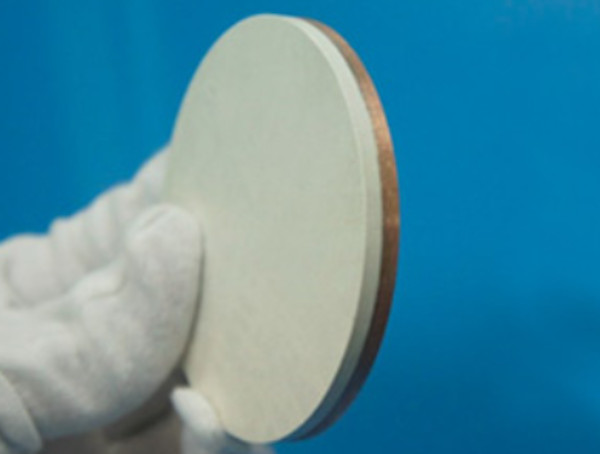

A comprehensive range of sputtering materials and sizes available

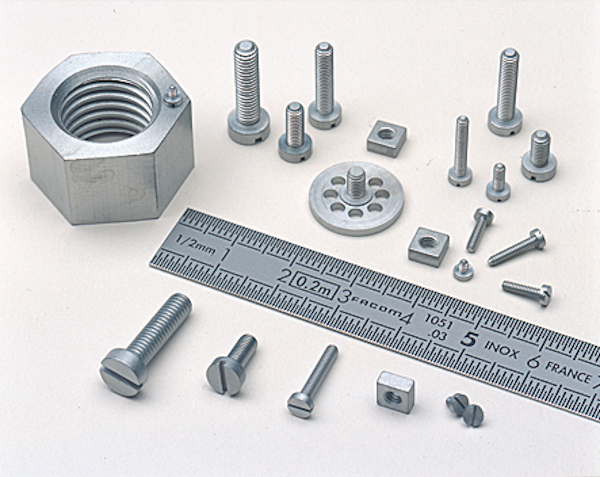

Micro machined components in strategic materials such as molybdenum, tantalum, titanium and niobium

Garnet crystals and substrates for epitaxy

We supply high purity evaporation materials for vacuum vaporation in a variety of shapes and sizes.

Indium and gallium antimonide. The InSb detectors are sensitive between 1 µm to 5µm wavelengths.

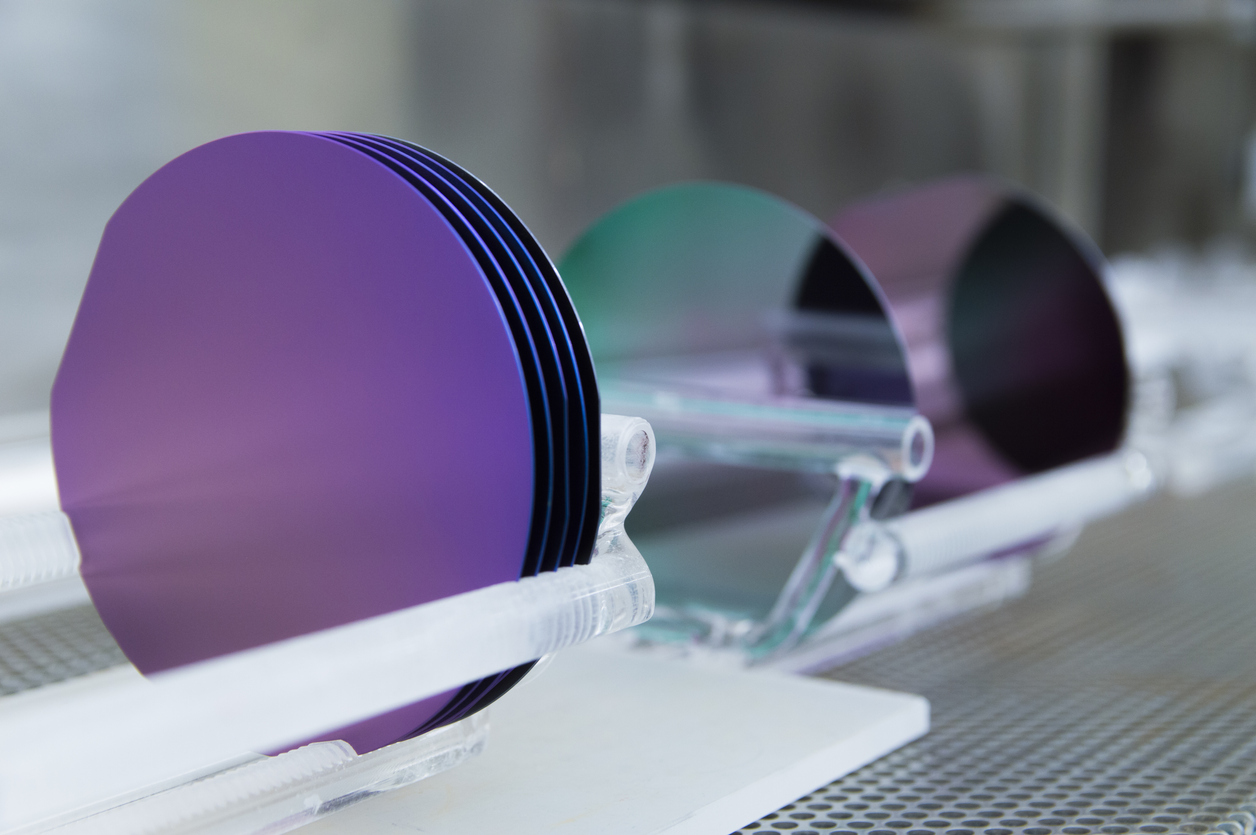

Czochralski (Cz) and float zone (Fz) for a large range of semiconductor applications

Scratch, indentation and wear testing all on one tool at nano and micro load ranges

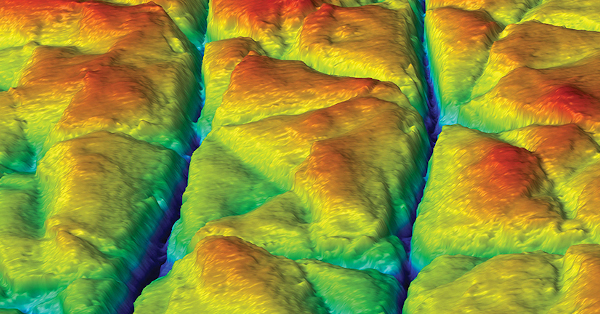

3D non-contact profilometers for collecting and analysing sample height data

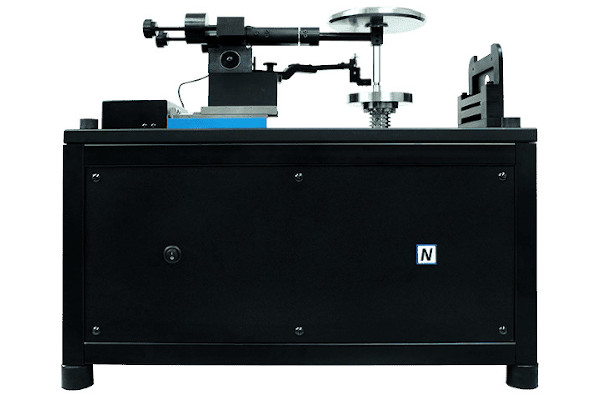

Robust, modular, and powerful pin on disc tribometers

Advanced 3D optical measurement solutions for quality assurance in production

Non-contact technology measuring real time strength and direction of electrical currents

Reproducing the wear interaction between a surface and the human finger

Measurement of surface tension between liquids and solids

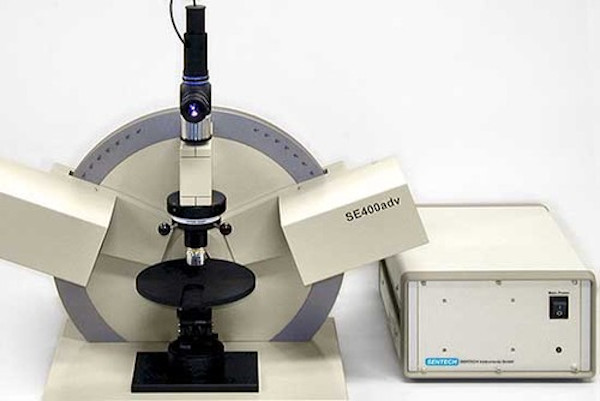

Determining thin film properties by change in polarisation of light

Measuring thin film properties by reflection

Tribology testing in ambient or tailored environments

Real life testing of finished products in respect of resistance to hand abrasion

Scratch & indentation for hardness, elastic modulus, adhesion, cohesion plus more

Gain a deeper understanding of your materials

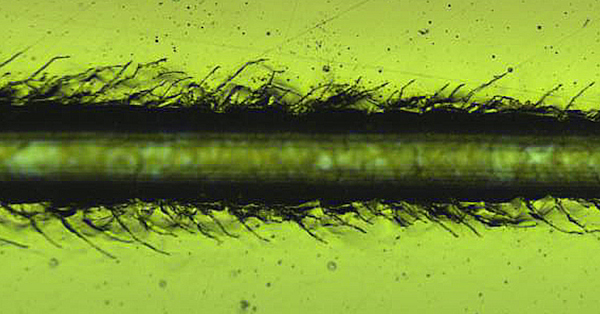

Measure surface roughness, form, profile, finish plus more

Low damage plasma enhanced chemical vapour deposition

Low damage etching and nano structuring

Deposition of layers in the nanometer scale

Deposition of coatings by the vacuum evaporation technique

Deposition of coatings by the sputtering technique

The dispersion, mixing, pulverization or emulsification of materials

Scintillator materials grown in crystal form

Scintillator material in organic form

Materials for the measurement of radiation dose

Sapphire in sheet, tube, rod and component form

LiF, Quartz or SiO2, InSb, Si, Ge, PET, ADP, Beryl, TlAP, RbAP, KAP and CsAP

Bespoke leak testing systems for small or large parts

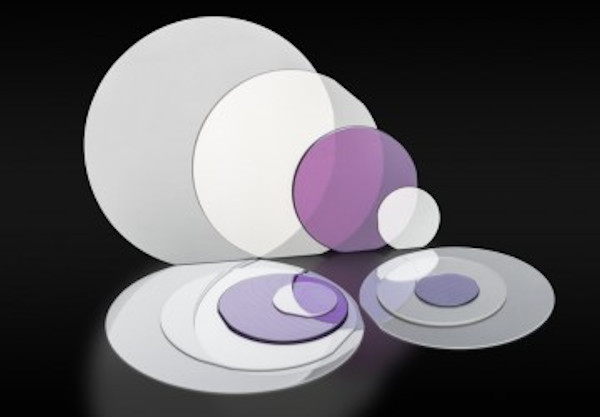

High performance laser optics from Alpine Research Optics

Powerful, easy to use and cost effective AI based image recognition

A comprehensive solution for laboratories using several types of microscope and profilometer

Benchmark technology for 2D and 3D surface texture analysis and metrology, seamlessly integrates with profilometers and other surface measuring equipment

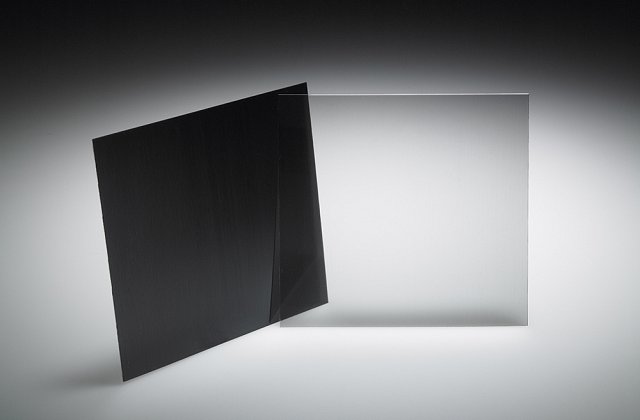

Conductive coating on one side to prevent EMI/RFI

Plastic optical filter with broadband AR coating on both sides

Privacy Glass & Light Control Film

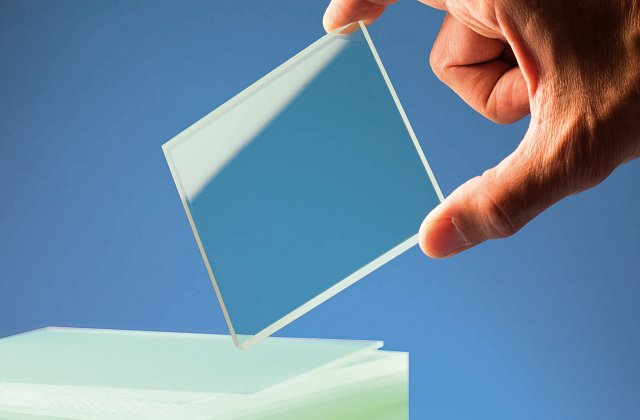

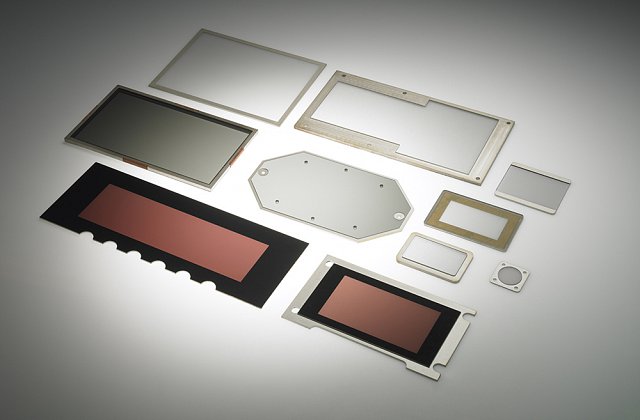

EMC shielded windows are designed for electronic displays, combining a high level of electromagnetic shielding with excellent contrast enhancement.

EMC and MRI windows are used to minimise radio frequency emissions generated by enclosed electronic equipment and also to protect electronic equipment from electromagnetic interference coming from external sources.

Windows are cast in-house as a one piece filter with a highly conductive micro-fine wire mesh totally encapsulated. This approach offers customers a more cost-effective and robust solution to shielding problems, totally eliminating delamination and optical imperfections which can affect ordinary laminated windows.

EMC shielded windows have a number of applications including but not limited to:

Shielding

Absorption of electromagnetic energy is mainly dependent on the mesh conductivity, wire diameter, weave density, electrical contact between intersecting wires, mesh material and edge terminations.

The EMC shielded windows effectiveness, measured by using the “Hole-in-the-Wall” technique, is typically between 60dB and 70dB from 100 KHz to 1GHz and 35dB up to 10GHz for blackened stainless steel meshes.

Optical Characteristics

It is important to colour match band pass filters to the particular display characteristics. Transmission, absorption and reflectance are dependent on the filter band pass colour, mesh density and non glare finish. Also, by casting the material as a one piece filter, the transmission is improved by reducing the number of internal reflecting surfaces from four to two compared to laminated windows.

Physical Design

Our EMC windows are supplied fabricated to customer requirements. Overall standard thicknesses are 2.5, 3, 4, 6mm. Other, non-standard thicknesses, from 1mm upwards, are also available to order together with an optional non glare finish.

Weight

For larger displays, weight can be an extremely important consideration in the design of shielded windows. Clear HSR and coloured acrylic filters weigh only half as much as glass. Additionally, an acrylic filter is up to five times as resistant to breakage as a comparable glass filter.

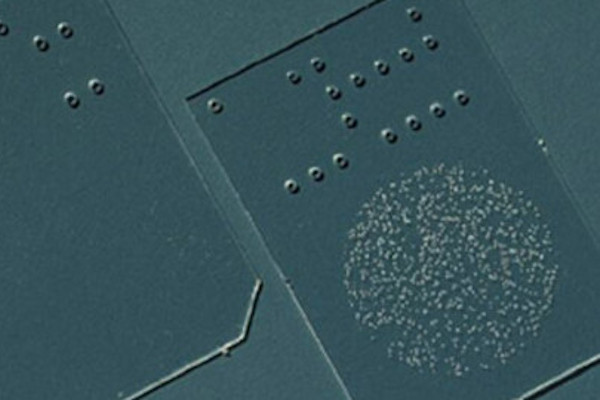

Mesh

Various types of mesh are offered which can be treated to produce a matt black non reflective finish. Alternatively, a standard metallic finish can be incorporated in band pass filters where the colour reduces the need for blackened mesh. Typically, the wire diameters range from .025mm to 0.5mm and the weave densities vary from 50 OPI (Opening per inch) to 200 OPI mesh. The mesh can be set at any angle up to 45° in more demanding applications to restrict the possibility of moiré fringes where this is important.

Edge Termination

In one piece filters, the conductive mesh is exposed along the edge of the filter after it is cut to size. A silver conductive busbar is added to the edge and then extended, if required, to the front or rear surface.

The conductive circuit from the mesh is then completed either through the busbar or else via a conductive elastomer gasket attached to the busbar. Other edge termination methods are also available.

Gasket

The conductive gasket consists typically of aluminium or monel wires, which are crimped for maximum pressure. The wires are oriented perpendicular to the mating surfaces and integrally bonded into a silicone elastomer. The elastomer acts either as an environmental seal or as a pressure seal. Again, other types of gaskets are also available.

We’re here and ready to provide information and answers to your questions

©Mi-Net 2023. All Rights Reserved.

Website by Fifteen.co.uk