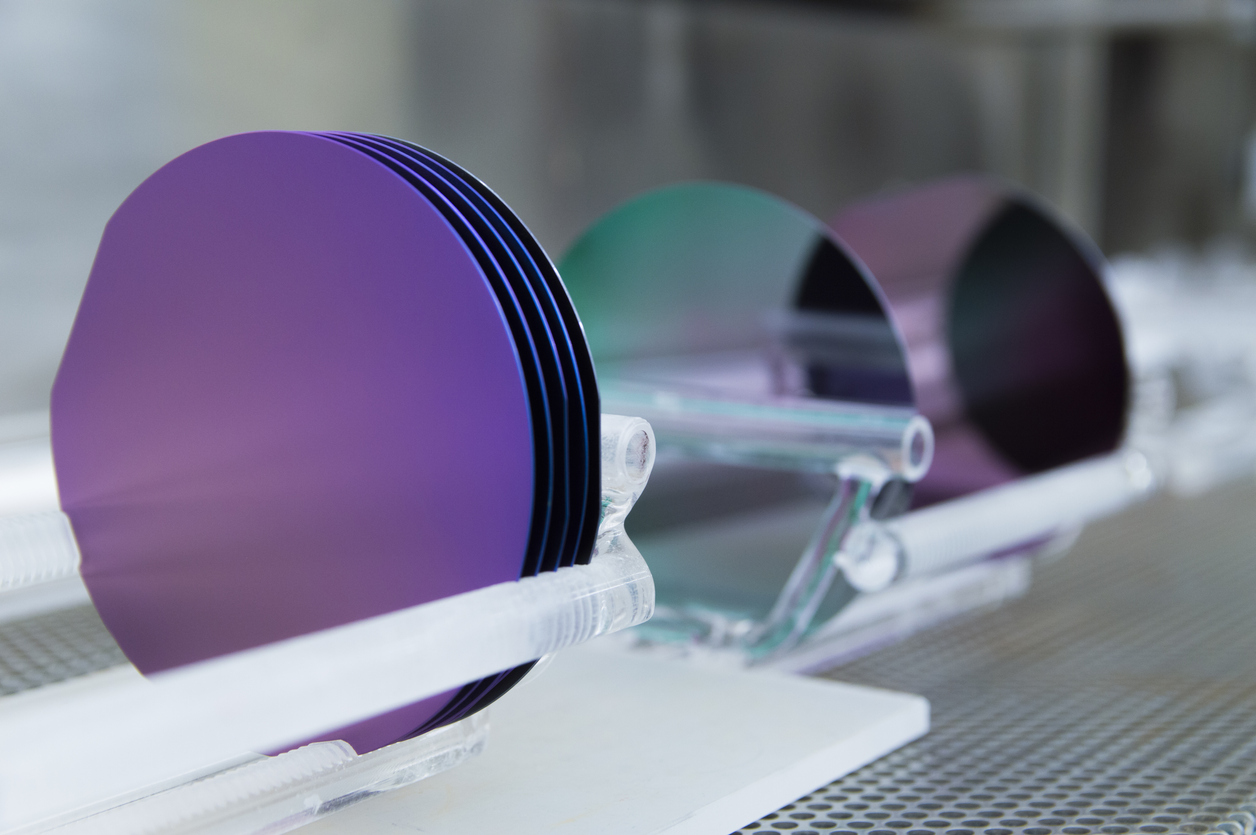

A comprehensive range of sputtering materials and sizes available

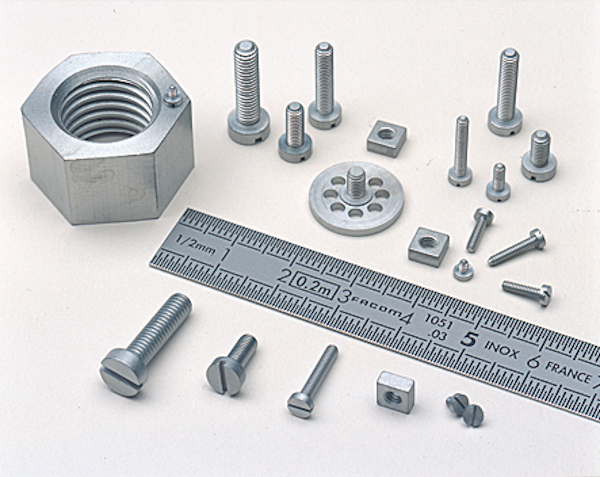

Micro machined components in strategic materials such as molybdenum, tantalum, titanium and niobium

Garnet crystals and substrates for epitaxy

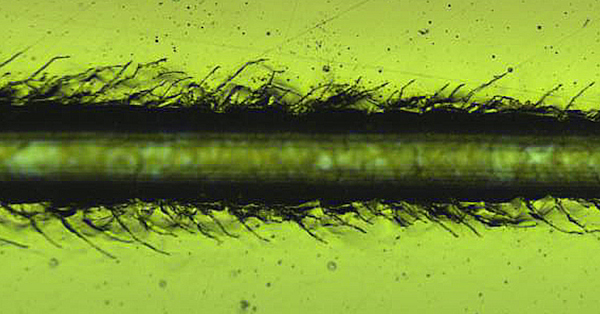

J-GRAPHENE is ahigh quality, low defect graphene dispersion

Czochralski (Cz) and float zone (Fz) for a large range of semiconductor applications

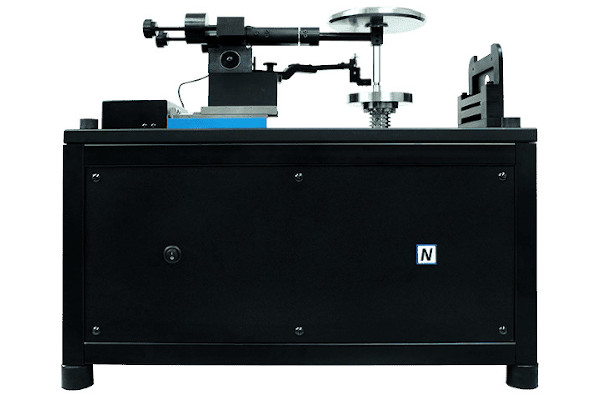

Scratch, indentation and wear testing all on one tool at nano and micro load ranges

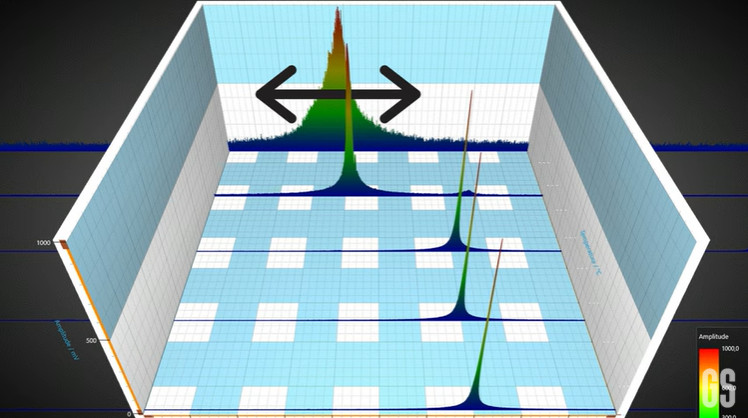

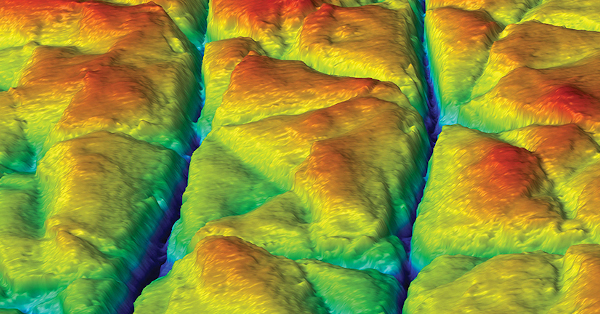

3D non-contact profilometers for collecting and analysing sample height data

Robust, modular, and powerful pin on disc tribometers

Non-destructive measurement of internal material properties

Advanced 3D optical measurement solutions for quality assurance in production

Non-contact technology measuring real time strength and direction of electrical currents

Reproducing the wear interaction between a surface and the human finger

Measurement of surface tension between liquids and solids

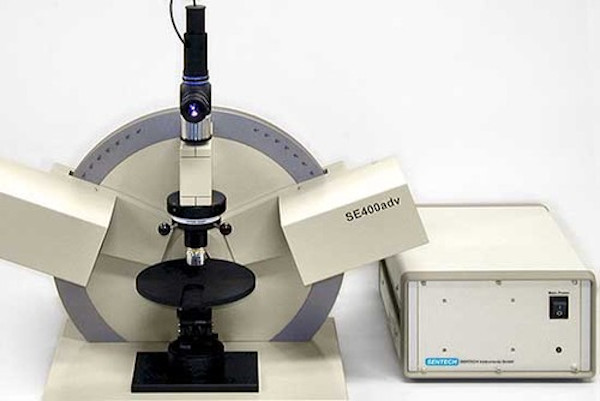

Determining thin film properties by change in polarisation of light

Measuring thin film properties by reflection

Tribology testing in ambient or tailored environments

Real life testing of finished products in respect of resistance to hand abrasion

Scratch & indentation for hardness, elastic modulus, adhesion, cohesion plus more

Gain a deeper understanding of your materials

Measure surface roughness, form, profile, finish plus more

Low damage plasma enhanced chemical vapour deposition

Low damage etching and nano structuring

Deposition of layers in the nanometer scale

Deposition of coatings by the vacuum evaporation technique

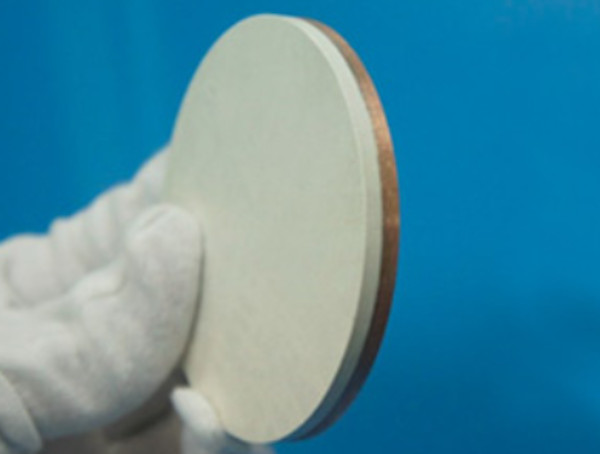

Deposition of coatings by the sputtering technique

The dispersion, mixing, pulverization or emulsification of materials

Scintillator materials grown in crystal form

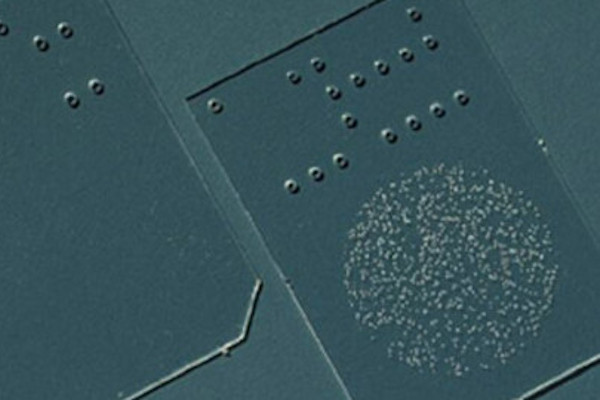

Scintillator material in organic form

Materials for the measurement of radiation dose

Sapphire in sheet, tube, rod and component form

LiF, Quartz or SiO2, InSb, Si, Ge, PET, ADP, Beryl, TlAP, RbAP, KAP and CsAP

Bespoke leak testing systems for small or large parts

Superb optical stability and unsurpassed shock and vibration resistance

The performance of a penta prism with more control and wavelength transmission

Beam alignment where three or more optical axes are required

Two-mirror optical assembly arranged at a 90-degree angle

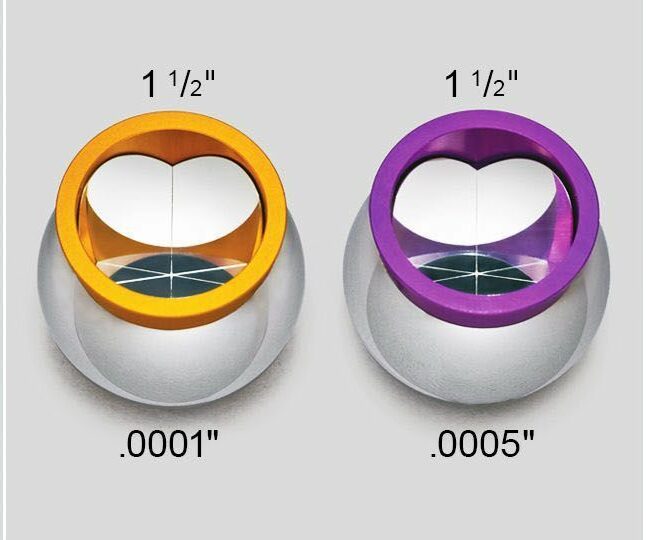

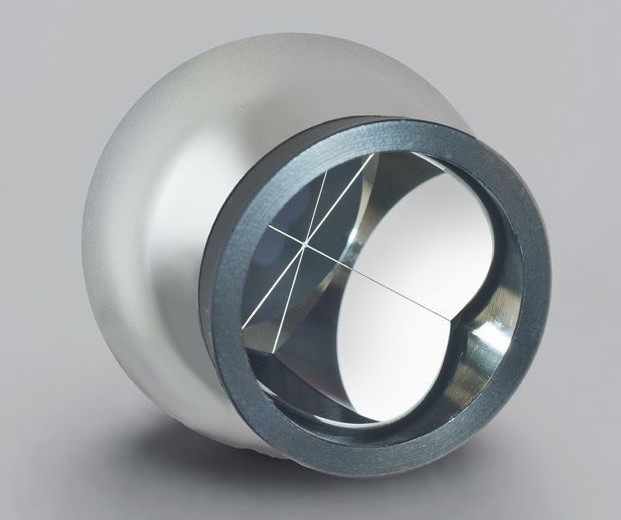

Ball mounted hollow retroreflectors

Reflects light back towards it’s source with minimal scattering

A comprehensive solution for laboratories using several types of microscope and profilometer

Benchmark technology for 2D and 3D surface texture analysis and metrology, seamlessly integrates with profilometers and other surface measuring equipment

Conductive coating on one side to prevent EMI/RFI

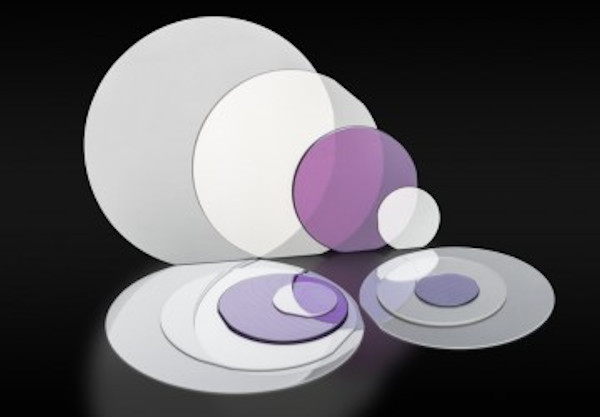

Plastic optical filter with broadband AR coating on both sides

Privacy Glass & Light Control Film

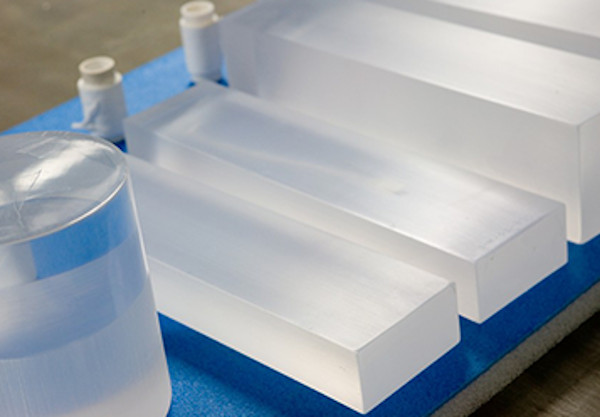

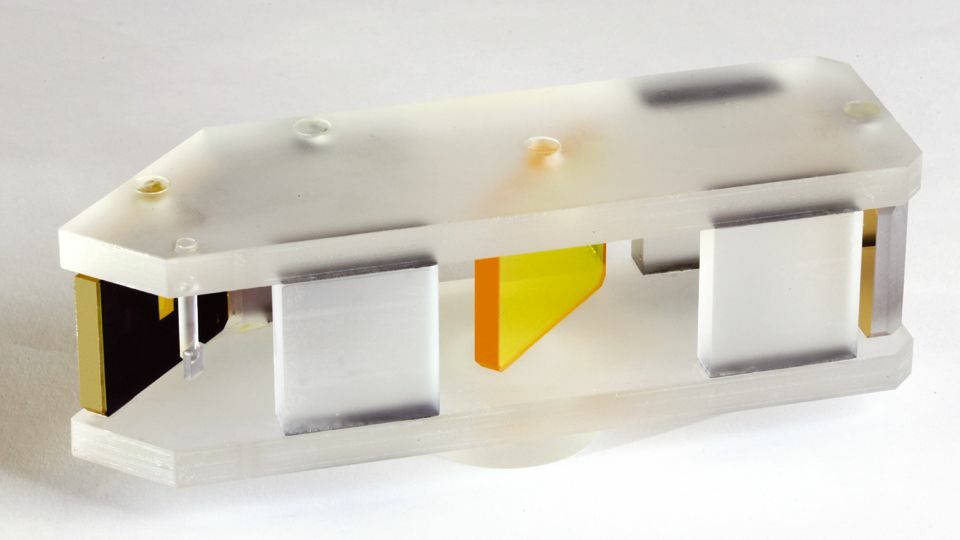

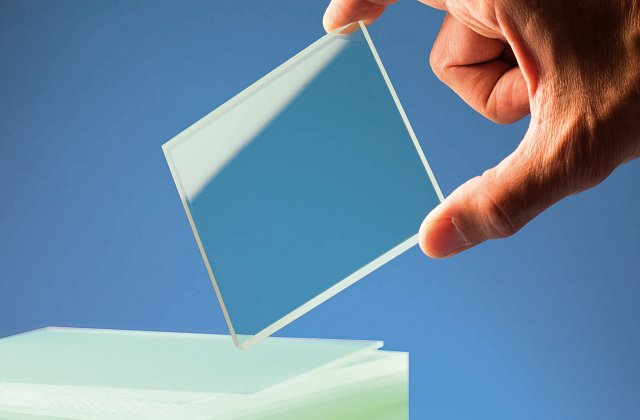

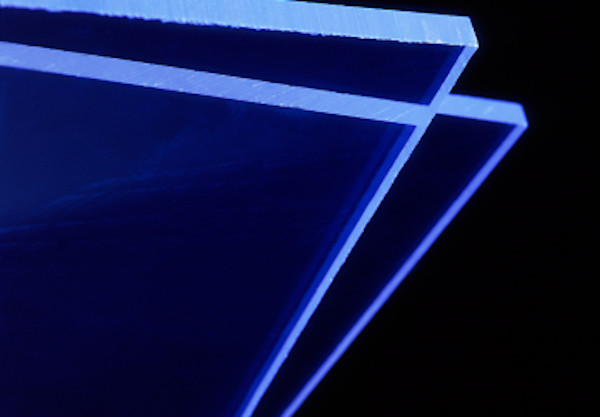

Plastic scintillator detectors consist of a solid solution of organic scintillating molecules in a polymerized solvent. They are easily cast into a variety of shapes and sizes making them an extremely useful form of scintillator. Cast sheets are the most common form with sheets being cut into smaller detectors where necessary. Other forms such as rods, blocks and custom shapes are also possible. Cast faces are usually untouched and edges can be diamond milled for an enhanced finish.

Plastic scintillators can be purchased by themselves or as part of completed detector assemblies incorporating light guides, photomultiplier tubes, special radiation entrance windows, light-tight wrapping, and electronics

Luxium Solutions (previously Saint Gobain Crystals) are the premier scintillation detection manufacture for ionizing radiation detection and provide high quality scintillation materials with superior resolution and advanced photo-sensor integration. Their core technology is the manufacturer of high performance engineering materials to solve their customers’ unique challenges. Luxium Solutions and Mi-Net have been working together in the UK and Ireland for over 30 years.

| Scintillator | Light Output % Anthracene1 | Wavelength of Maximum Emission, nm | Decay Constant, ns | Bulk Light Attenuation Length, cm | Refractive Index | H:C Ratio | Loading Element % by weight | Density | Softening Point °C |

|---|---|---|---|---|---|---|---|---|---|

| BC-400 | 65 | 423 | 2.4 | 250 | 1.58 | 1.103 | 1.023 | 70 | |

| BC-404 | 68 | 408 | 1.8 | 160 | 1.58 | 1.107 | 1.023 | 70 | |

| BC-408 | 64 | 425 | 2.1 | 380 | 1.58 | 1.104 | 1.023 | 70 | |

| BC-412 | 60 | 434 | 3.3 | 400 | 1.58 | 1.104 | 1.023 | 70 | |

| BC-416 | 38 | 434 | 4.0 | 400 | 1.58 | 1.110 | 1.023 | 70 | |

| BC-418 | 67 | 391 | 1.4 | 100 | 1.58 | 1.100 | 1.023 | 70 | |

| BC-420 | 64 | 391 | 1.5 | 110 | 1.58 | 1.102 | 1.023 | 70 | |

| BC-422 | 55 | 370 | 1.6 | 8 | 1.58 | 1.102 | 1.023 | 70 | |

| BC-422Q | 11 | 370 | 0.7 | < 8 | 1.58 | 1.102 | Benzephenone,0.5%* | 1.023 | 70 |

| BC-428 | 36 | 480 | 12.5 | 150 | 1.58 | 1.103 | 1.023 | 70 | |

| BC-430 | 45 | 580 | 16.8 | NA | 1.58 | 1.108 | 1.023 | 70 | |

| BC-440 | 60 | 434 | 3.3 | 400 | 1.58 | 1.104 | 1.032 | 99 | |

| BC-440M | 60 | 434 | 3.3 | 380 | 1.58 | 1.104 | 1.039 | 100 | |

| BC-444 | 41 | 428 | 285 | 180 | 1.58 | 1.109 | 1.023 | 70 | |

| BC-452 | 48 | 424 | 2.1 | 150 | 1.58 | 1.134 | Lead, 2% | 1.050 | 60 |

| BC-480 | ** | 425 | – | 400 | 1.58 | 1.100 | 1.023 | 70 | |

| BC-482A | QE=.86 | 494 | 12.0 | 300 | 1.58 | 1.110 | 1.023 | 70 | |

| BC-490 | 55 | 425 | 2.3 | NA | 1.58 | 1.107 | 1.023 | 70 | |

| BC-498 | 65 | 423 | 2.4 | NA | 1.58 | 1.103 | 1.023 | 70 |

| Standard Sizes | ||

|---|---|---|

| 0.5 mm | ± 0.1 mm | 30 x 60 cm |

| 1 mm | ± 0.1 mm | 30 x 60 cm |

| 1.5 mm | ± 0.25 mm | 30 x 101 cm |

| 2 mm | ± 0.25 /- 0.3 mm | 45 x 101 cm |

| 3 mm | ± 0.38 mm | 63 x 101 cm |

| 5 mm | + 0.56 / – 0.46 mm | 63 x 203 cm |

| 6.4 mm | + 0.64 / – 0.51 mm | 63 x 203 cm |

| 10 mm | ± 0.51 mm | 63 x 203 cm |

| 12.7 mm | ± 0.64 mm | 63 x 203 cm |

| 20 mm | ± 0.73 mm | 63 x 203 cm |

| 25 mm | + 0.76 / – 1 mm | 63 x 203 cm |

| 38 mm | ± 0.76 mm | 63 x 203 cm |

| 50 mm | ± 2 mm | 63 x 203 cm |

| 75 mm | ± 2.5 mm | 60 x 101 cm |

| 100 mm | ± 3.8 mm | 60 x 101 cm |

| 125 mm | ± 6 mm | 60 x 101 cm |

| 150 mm | ± 6 mm | 60 x 101 cm |

| Large Cast Sheet Size Range | ||

|---|---|---|

| Thickness Range | Maximum Width | Maximum Length |

| 1 – 5 cm | 30 cm | 450 cm |

| 0.5 – 5 cm | 45 cm | 400 cm |

| 0.5 – 5 cm | 60 cm | 300 cm |

| 1 – 2.5 cm | 100 cm | 200 cm |

| 1 – 3.8 cm | 120 cm | 120 cm |

Finish for 2 parallel large surfaces:

Best as cast surface finish is optically clear and quite flat. Sheet material is cast to thickness in between two glass sheets, so this results in a glass like polished surface.

Diamond milled cast faces is possible. The finish is flatter than as-cast, optically clear but not as clear as with as-cast. small tool marks may be visible under magnification.

Finish for edges:

Best diamond milled edges has an optically clear surface finish that is quite flat.

Rough or saw-cut edges has a rough finish that is not optically clear and so further processing by the user is recommended. This is the more cost effective option,

Other products in the Saint Gobain Crystals range.

We’re here and ready to provide information and answers to your questions

©Mi-Net 2023. All Rights Reserved.

Website by Fifteen.co.uk