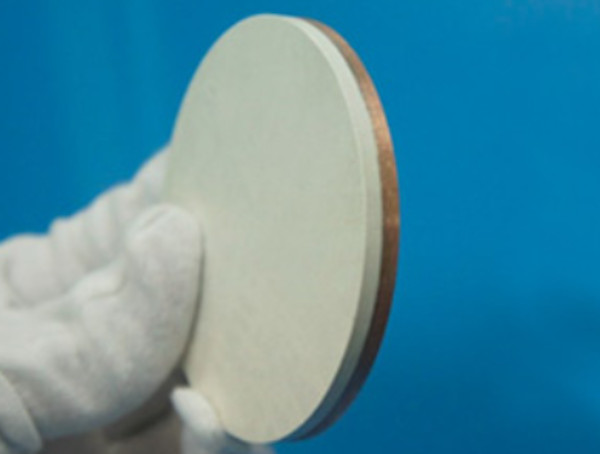

A comprehensive range of sputtering materials and sizes available

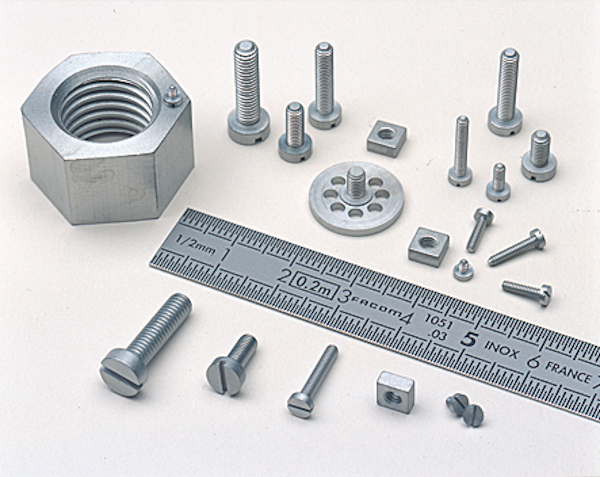

Micro machined components in strategic materials such as molybdenum, tantalum, titanium and niobium

Garnet crystals and substrates for epitaxy

We supply high purity evaporation materials for vacuum vaporation in a variety of shapes and sizes.

Indium and gallium antimonide. The InSb detectors are sensitive between 1 µm to 5µm wavelengths.

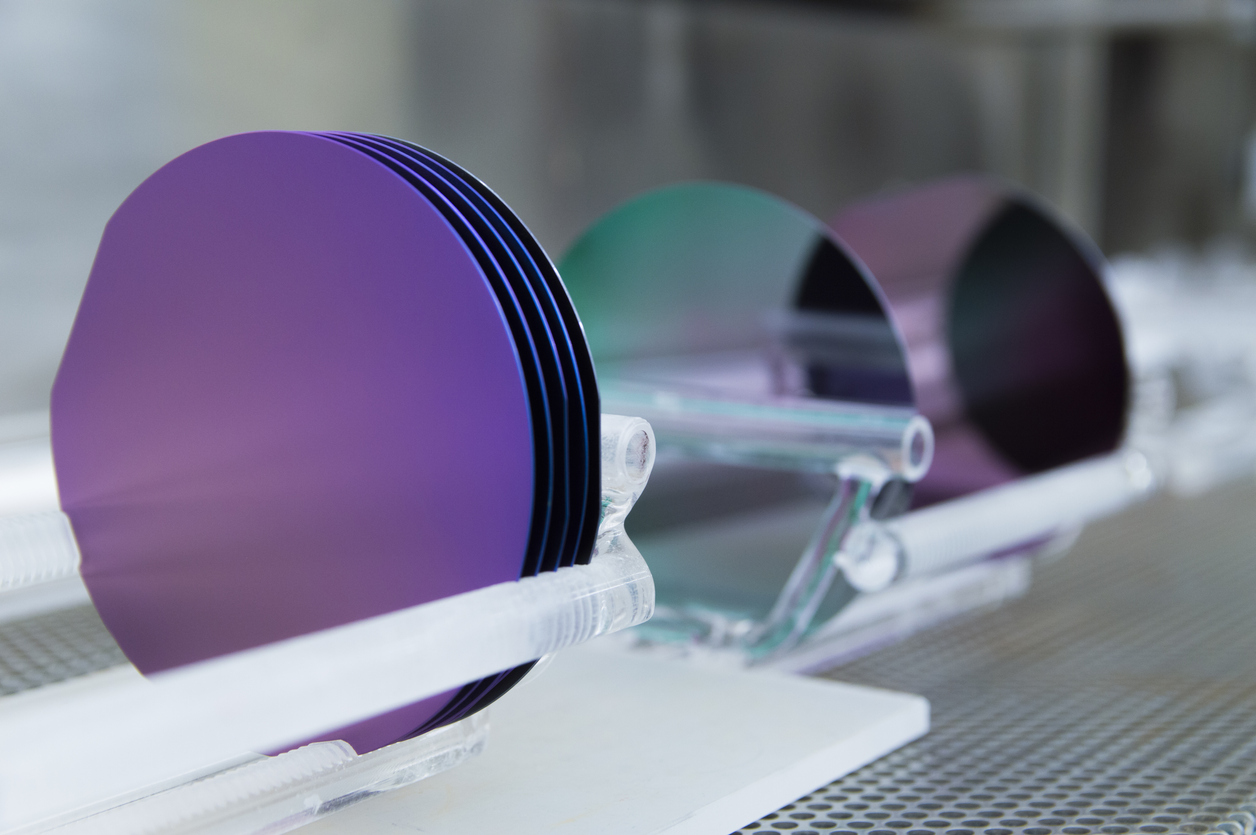

Czochralski (Cz) and float zone (Fz) for a large range of semiconductor applications

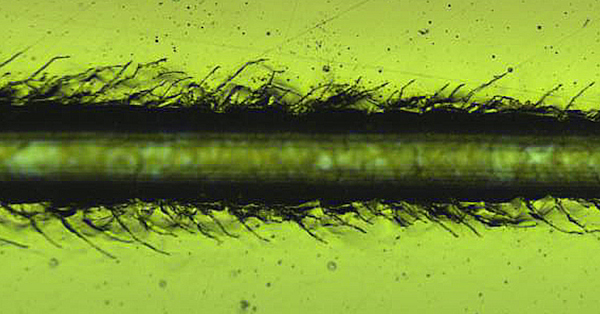

Scratch, indentation and wear testing all on one tool at nano and micro load ranges

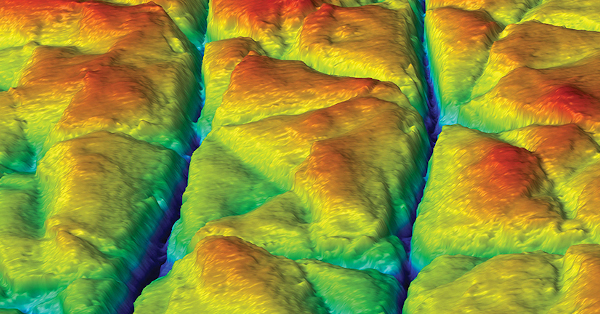

3D non-contact profilometers for collecting and analysing sample height data

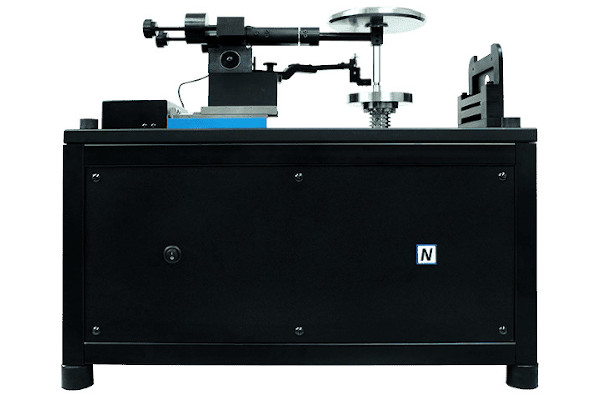

Robust, modular, and powerful pin on disc tribometers

Advanced 3D optical measurement solutions for quality assurance in production

Non-contact technology measuring real time strength and direction of electrical currents

Reproducing the wear interaction between a surface and the human finger

Measurement of surface tension between liquids and solids

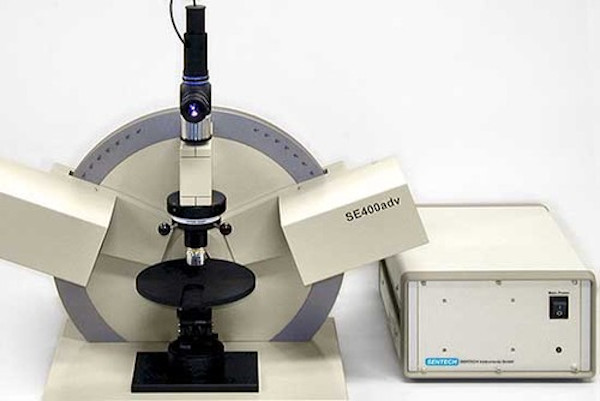

Determining thin film properties by change in polarisation of light

Measuring thin film properties by reflection

Tribology testing in ambient or tailored environments

Real life testing of finished products in respect of resistance to hand abrasion

Scratch & indentation for hardness, elastic modulus, adhesion, cohesion plus more

Gain a deeper understanding of your materials

Measure surface roughness, form, profile, finish plus more

Low damage plasma enhanced chemical vapour deposition

Low damage etching and nano structuring

Deposition of layers in the nanometer scale

Deposition of coatings by the vacuum evaporation technique

Deposition of coatings by the sputtering technique

The dispersion, mixing, pulverization or emulsification of materials

Scintillator materials grown in crystal form

Scintillator material in organic form

Materials for the measurement of radiation dose

Sapphire in sheet, tube, rod and component form

LiF, Quartz or SiO2, InSb, Si, Ge, PET, ADP, Beryl, TlAP, RbAP, KAP and CsAP

Bespoke leak testing systems for small or large parts

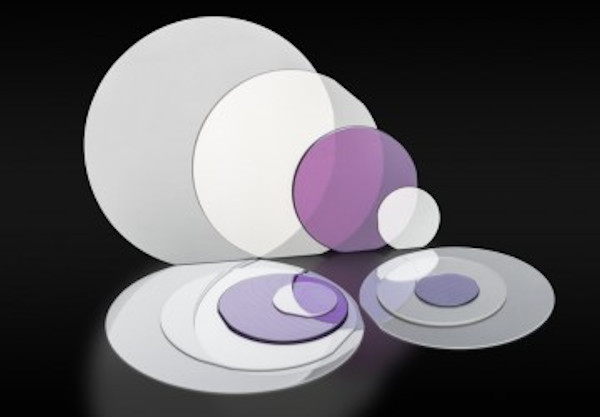

High performance laser optics from Alpine Research Optics

Powerful, easy to use and cost effective AI based image recognition

A comprehensive solution for laboratories using several types of microscope and profilometer

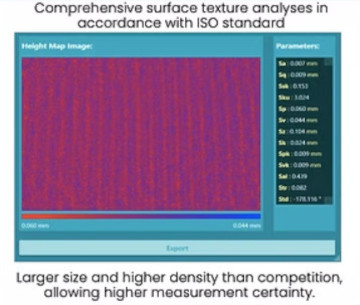

Benchmark technology for 2D and 3D surface texture analysis and metrology, seamlessly integrates with profilometers and other surface measuring equipment

Conductive coating on one side to prevent EMI/RFI

Plastic optical filter with broadband AR coating on both sides

Privacy Glass & Light Control Film

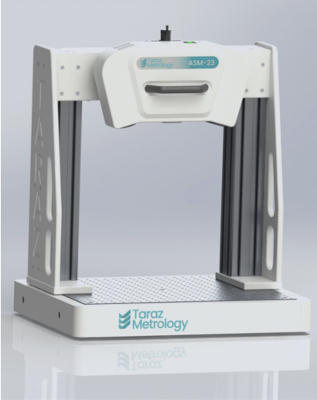

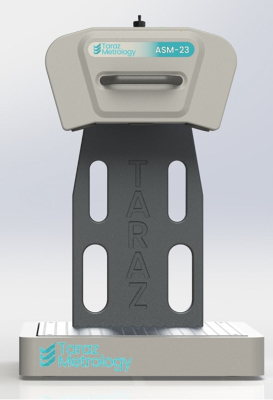

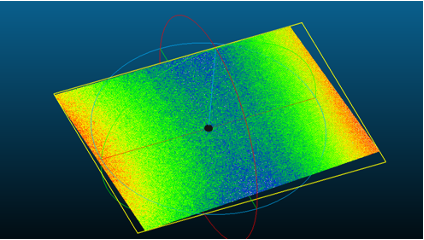

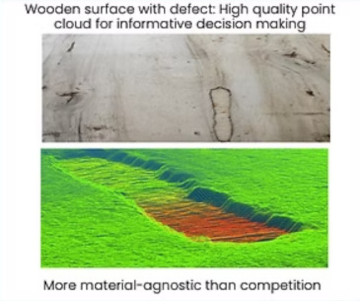

The Areal Surface Measurement System (ASM) is Taraz’s most advanced blue-light fringe projection system engineered for surface and topography measurements. This system can be used off-line or in-line with precision and efficiency across a variety of industries including automotive, coatings, additive manufacturing and aerospace.

ASM can also be used with Photogrammetry.

The ASM is fast and tunable with full measurement traceability adhering strictly to NPL measurement guidelines.

Taraz Metrology was born out of the University of Nottingham’s Manufacturing Metrology Team, combining cutting-edge research and proven expertise. They provide high-quality measurement solutions that play a critical role in quality assurance in production processes globally, driving efficiency and sustainability across industries.

Taraz’s first fringe projection system was the IM 1 developed in 2019. This system was developed as a solution to in-process and post-process metrology inspections for additive manufacturing applications.

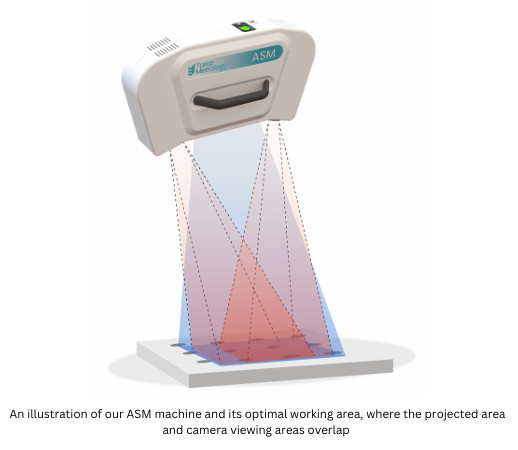

The Taraz ASM fringe protection system works as follows:

1) Projecting the pattern

The process begins with a high-precision projector casting a specific pattern onto the object being measured. This pattern, composed of a series of fringe lines, is critical for capturing the object’s surface details with accuracy.

2) Capturing the images

As the pattern is projected, a specialised set of cameras simultaneously captures multiple images of the object. Each image, made up of a fine array of pixels, encodes the fringe patterns projected onto the surface, providing comprehensive data for analysis.

3) Analysing and measuring

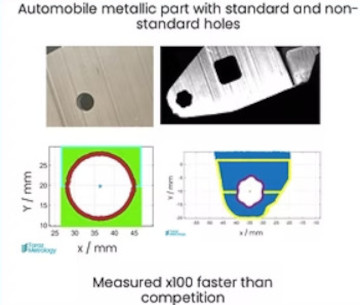

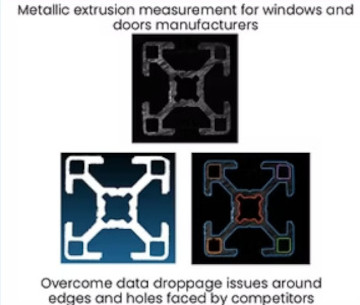

Finally, the captured images are processed by advanced software that uses triangulation techniques to determine the exact shape of the object. The result is a set of highly accurate and universal point clouds, revealing the intricate surface characteristics in fine detail. This includes better definition around the edges and more refined hole boundaries, contributing to the overall precision of the measurement.

| ASM Version | Standard-resolution ASM | Higher-Resolution ASM | Wide-field ASM |

| Point cloud resolution | 70μm | 10μm | 400μm |

| Measurement area | 255mm x 174mm | 70mm x 50mm | 1200mm x 800mm |

| Cycle time (capturing) | 2 seconds | 2 seconds | 2 seconds |

| Cycle time (point cloud generation)/PC dependent | 6 seconds | 6 seconds | 6 seconds |

| Global Specifications | Value |

| Operating temperature | 22°C – 30°C |

| Portability | Available |

| Output File | Point Cloud (.ply) |

| Measurement Noise | 2μm |

The Taraz ASM system is also powered by Photogrammetry, offering precise measurement and analysis by capturing images of objects from multiple perspectives. This method allows for accurate three-dimensional reconstructions, ensuring high-quality 3D measurements with exceptional precision. By utilising advanced geometric calculations, their system can deduce the exact position and dimensions of objects in three-dimensional space.

|

1) Capturing Multiple Perspectives The process begins by recording images of the object from different angles using either multiple cameras or by repositioning a single camera. Each view focuses on specific features of the object, capturing essential details from various perspectives. |

|

|

2) Geometric Analysis Once the images are captured, our system uses sophisticated algorithms to evaluate the distances between cameras and specific points of interest on the object. Through precise geometric calculations, the exact position of each point is determined. |

|

3) 3D Reconstruction Finally, the analysed data is used to reconstruct a detailed and accurate three-dimensional representation of the object. This 3D model provides a comprehensive view, allowing for precise measurements and in-depth analysis. |

|

Other instruments in our Testing & Analysis range

We’re here and ready to provide information and answers to your questions

©Mi-Net 2023. All Rights Reserved.

Website by Fifteen.co.uk